So I have been asked by several people about my Fiat X19 / honda B16 swap. I decided that I should just put the story here. Yes, story, this is not meant to be a technical document even though it might contain some technical stuff. First of all, I would like to thank several people and I will probably forget a few (sorry). First and foremost, my wife Kendra for putting up with my addiction to fiats. Second (only because he doesn’t feed me or take care of me) is my best friend and partner in crime, Dale Mund.

It is his mechanic background as well as a good garage in which to work in made this possible. I could not have done this without the help of several people on xwebforums.com. Especially Mr. Biswanger who supplied the PowerPoint on his conversion. (http://autox19.com/b16) The people of hondaswap.com for their help on the honda end. Rywire.com for the custom wiring harness. DriveshaftShop.com for the custom 1/2 shafts. Jeff Miller for his aide and advice on the exhaust. Elise for finding the original X that was converted. And the Many friends I have that I have annoyed through these years.

So why the swap? I was running the X with dual DCNF carbs and it was running pretty darn good. sounded awesome. One day it started backfiring. after weeks of trying to troubleshoot the backfiring I was thinking of a swap. the B16 swap was done before, along with other swaps as well. What I liked about the B16 swap was it was relativity inexpensive, required no major structural changes and most of all it kept the spirit of the X by being a high revving engine. After many nights of thought, I decided to pull the switch. First I sold the dual carbs. Then I decided to really make it hard to go back I pulled the engine. When I pulled the engine I found the reason for the backfires. although I checked the header for leaks, I didn’t check the o2 bung because I didn’t have fuel injection and it was capped with w bolt. Well, the bolt fell out. Oh well, carbs are gone and engine pulled. Now to sell the engine and trans. It went pretty quick as I really didn’t want to make money, just wanted it gone so I couldn’t turn back.

Next step was to find an engine and trans. I Looked at the importers but I was seeing if I could find it cheaper. I found and engine, and someone else with a transmission for about $1000 total. not a bad deal. The engine was a OBD1 JDM and the trans was a mystery. Well it gave me a place to start. even if they were only to be a mule to get the mounts made. About 3 weeks later, I found a running honda with a OBD0 JDM. Called the guy up and he said it ran great, except it only went to 4000 RPM. I knew it was probably in limp mode. didnt know why but I thought I would check it out. $1500 later and I was driving the purple pimp mobile home. i ran great (except limp mode) but was lowered too much and had funky ground effects. yeah, I am getting old. Now before we took it out, Dale suggested I get this one running right before we yank it out. He keeps me on track. I replaced the TPS sensor and reprogrammed the ECU to not check for O2 sensor and all was well, limp mode was off. Side note, it came with a chipped obd1 ECU. so now on to the swap!

pimpmobile

Ripping the engine/trans out was pretty easy.

So we moved on to prepping the X. We had our first issue. After disassembling the back ens and removing a few covers, we found that the cross member was pretty much non existent.

That is from where the previous owner tacked on a few pieces for a little strength. After much thought and a few feeble attempts at fixing it, we gave up. Now to make a new cross member. The rear suspension is partially held up by this member so we now have to figure out how to make sure the suspension stays straight. Dale came up with a pretty cool jig that held the suspension in place while we cut the old member out.

Grabbing some very large steel tubing (probably too big) we built a new cross member. Used the jig to keep the suspension points in place while we welded the crossmember in place.

Starting to get real fun! I cut anything from the engine compartment that wasnt needed for it to run, including the fiat mounts. We then slid the engine and trans in place. just like was noted from other that did the swap, we needed to notch the frame on the transmission side.

Other than that it looked pretty good. from there we started mocking up the new mounts. things worked out pretty well, bought new bushings, fabricated the mount that bolts on to the transmission.

now we bolted the engine in. It fits! woo hoo!! oh wait. we need to put the intake on. ugh. Looks like we positioned our engine just a little higher than the one in the powerpoint. Well, this wasn’t meant to be a show car, so POOF cut that cross member out, replace it with a bar and go with hood clips for the engine cover. there, problem solved.

Now for electrical. there are SEVERAL websites that show wiring diagrams for the honda b series. I was thinking this would be a great time to hone my electrical skills. Yeah. that looked good on paper. After several months of struggling I had a working harness. except it looked REAL ugly.

at this time I called up rywire and piked up a race harness. yeah, it was expensive, but it was right. and it looked good.

Now for fuel. I am going to eventually go with a fuel cell up front, but for now the stock tank will work. picked up a Walbro pump as the X had a carbed engine and that pump wont work on a fuel injected engine. (i had an electrical rather than mechanical) Had a new line made forgoing from the pump to the honda filter. I kept the stock filter because it is a good filter and there was an easy spot to mount it. Now the moment of truth. Time to start it. We weren’t trying to drive it, so nothing else was needed right now, even the coolant lines weren’t run. It didn’t start. more trouble shooting. After sending the harness back to rywire with my ECU so they could test it, we found it wasn’t on the ECU/wiring end. We were not getting spark. New Dizzy time. Now we had spark! still wont run. Compression test showed we had compression, but not as much as we should. Static timing. Yup. timing was off. looks like the belt slipped at some point in time. new belt as well as a new crank pulley (the other was cracked so a new one would be best) and we had compression and she started up. YAY!

Onto Coolant! yeah, this was an interesting one. how to route it when the 2 engines werent exactly the same. the fiat had more manifolds to support the fiat system. We ended up using the stock stainless Reservoir Tee’d into the return line from the radiator. then plugged the top nipple that we wouldn’t use. Started back up and no leaks! of course we didn’t let it run too long. not sure if the thermostat opened but I digress. We added a tunerview II so we could monitor things because nothing really connected to the fiat dashboard.

Now to get to the 1/2 shafts. I left this until later so I could prolong the $800 expense as long as possible. I measured and ordered them. they were delivered pretty fast and looked great. Rather than put them in, then take the right back out, we decided to remove everything now that everything “worked”. we took the engine out to clean up the engine compartment. because of how we have it routed, it only took about 2.5 hours form start to the engine being out. From there I cleaned up some welds, removed a few more extra wires and such. I put a new firewall insulation and added the hood clips to hold the engine lid and trunk.

Now the engine goes back in. Slick as snot. now the 1/2 shafts. not so slick. they didnt fit. Not even close. UGH. it has now been a little over a year since I bought them. This is not going to be good. Called them up and they were wonderful. They said this kind of project timelines happen all the time. Well after 3-4 shots of trying to get it right (finally shot a video explaining why they didnt fit) It was correct and they fit like a glove. EXCEPT… yup more issues. with the suspension fully unloaded, the shafts couldn’t get enough angle because of the CV covers. Driveshaft Shop gave me high performance road race covers which are much stronger than normal, but doesn’t allow the angles I needed. So I replaced those with VW off road covers. Perfect.

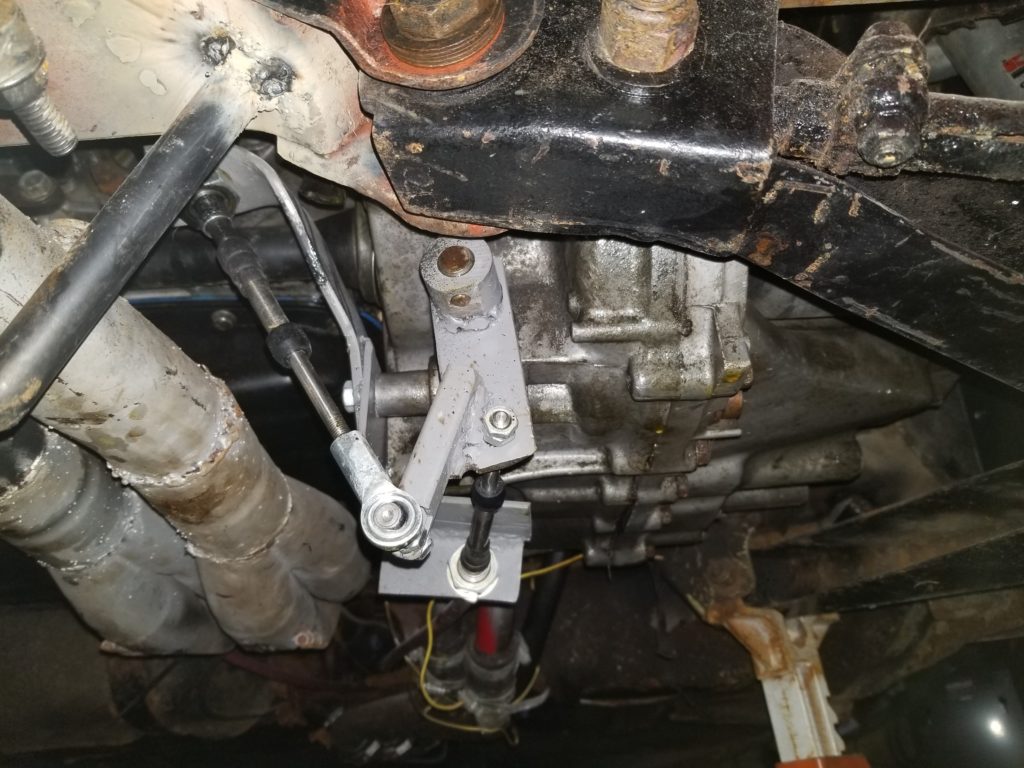

Now onto linkage. In theory it is pretty simple. When you move the trans form the front to the back, Where a push from the driver seat to the selector rod did A, a pull to the selector rod will do A. So reverse everything.. NO. wait. because the shifter that once was routed to the front is now going to the back, its function is reversed as well. 2 reverses equals same! playing around between the fiat shifter and the honda shifter, I decided to stay with the fiat shifter. Only one rod to manipulate. I did have to shift where it is mounted a little in order to get it headed to the right spot as straight as possible, but it worked.

Exhaust. Before I go into that, I am going to explain a little of my plans. I plan on rebuilding the other B16 I have and turbo charging it to a moderate 250 HP. (in a 2000lb car). this is important because I would like the exhaust to be able to be used after I do this. i.e. the downpipe going to the same place as the header does now. so I threw the header on and. yup another issue. it sticks too far back. as in the flange mount is actually behind the car. the fiats back curves in, so it wasnt behind the whole car, but behind where the body workj is. either way, it wont work. After consulting with many people, it was decided to hack the header and shorten it. yes I will lose “the optimum length” but I am planning on going turbo in a year or so anyway. now for the exhaust. several ideas where floating around. one was vibrant has a muffler that has a side in and 2 out. We mocked it up and it actually seemed like it would work, probably have to do some modification where it exits, but it should work. I pulled the trigger. This was rough as it was pretty costly (because it was polished stainless) and if it didnt fit. that would suck. It came in. and it actually fits better than expected.